Aloha all, 2017 was a busy year. Many thanks to you all for the continued support and patronage.

I truly appreciate the opportunity to do good work.

Today I want to share pics of a new speculative tansu completed beginning of December.

Available for immediate sale, ready to crate and ship to you any where in the world.

The work is a isho kasane dansu. A stacking clothing chest. Its a fairly orthodox work.

The tansu measures 18x36x42 inches. Made from Mango, silk oak,milo, koa, axis deer antler and about 25lbs of steel. The base finish ( toner) is kakishibu with bengara and susu that was used as a grain filler and colorant. Top coat is a garnet shellac polish.

The hardware is entirely hand forged most of which I made here in my shop excepting the warabite style handles I acquired from my supplier in Japan. It was an exploration piece for the sake of working through the rudiments of making the metal fittings. They were entirely hand cut with chisel and file from 16ga. sheet steel. 535 hand forged tiny round head nails that attach the 70 plus individual plates to the chest. I believe all in all there is close to 90 pieces of hardware on the chest.

The "safe" door latches with a slide bolt with forged knob and floral escutcheon.

The dominant design pattern is of the eyokurigata family.

This was a prevalent popular pattern style in the 1800's. The door pull center of the door, I carved from axis deer antler a hunter friend brings back from Lanaii for me.

I've made, over the years, many pieces of hardware but this a first effort to bring forth a full suite for a single chest. The parts them selves took most of three weeks to make.

I chose 16ga mild steel plate for the hardware because it gives the work a 19th century feel. The plates on late Edo chests tended to be thicker prior to modern sheet metal fabrication when all the sheet metal was forged from ingot. Fortunately we could source the sheet steel from Hilo Steel.! I can not imagine having to make the raw material as well.

As with all my tansu, the cabinet was made from rare hard to find single wide boards from my horde.

It is unusual to have flat sawn material to show such figure normally more prevalent in quartersawn cuts like used on the drawer faces.

The long square cornered bails are to enable your servants to carry your tansu from one location to another. No, really. Simply lift the handles up and slide a rod thru one to the other across the top of the individual chest and then your two loyal retainers can carry your garments from home to beach house upon their shoulders...... them were the days.

Behind the door we have two smaller drawers with Hirute shape handles and for contrast I chose to go with a natural mango and clear finish.

And every-bodies favorite the hessokuribako ( bellybutton chestnut box) made from Milo behind the top drawer.

The drawers are hand cut dovetails, really the only departure from the orthadox. A nod of sorts to my New England heritage, but more reasonably the best way to build a drawer. I used a high figure silk oak for beauty on the inside but just love the silk oak for a drawer material in general. It cuts and planes wonderfully and is a contrasting color to the primary materials.

Maybe hard to see from the pics but I rubbed the finish on the tansu to two different levels of sheen. The carcass is a satin with a mac nut bee's wax polish while the drawer fronts and door are more of a semi-gloss rubbed with a perpote.

Here's one last pic from a different angle and different light. I've really enjoyed having the new work in the house for the past month. The color changes depending on the angle in which the tansu is viewed from a light brown to an amber.

Many thanks for taking a look. And once again I wish you all a very good year.

If you'd like to stick around, scroll down and you will find some progress pics taking during the construction.

Below shows the traditional gomai corner contruction found on quality period tansu. Essentially means "5 flats" which is the step up from sanmai " three flats"

The backs of old tansu were simply nailed on with wooden nails. The back panel then becomes very prone to crack lacking ability to move as the wood expands and contracts from the changes in humidity from one season to the next. My solution is to make a flush fit back panel floated in grooves to allow movement but retain the look of jidai tansu ( period tansu)

Drawers are traditionally nailed together as well. Though more an more today you'll see dovetails being used. Though typically they are rather coarse and clunky looking. I like mine with a slender pin and the double tails on either end really lock the corner together well. The bottom panel floats in the groove keeping the drawer bottom from cracking for the life of the tansu.

Everything is hand planed inside and out prior to assembly.

Interior components are prefinished prior to assembly.

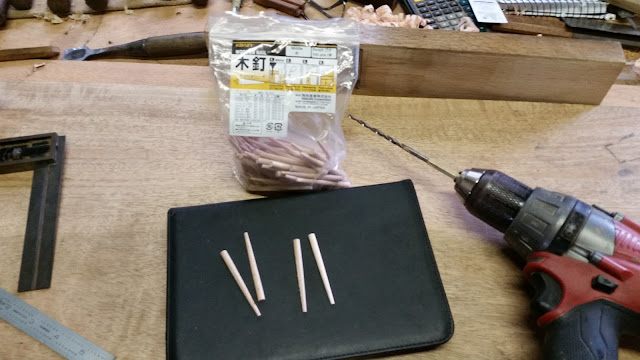

Below are Kikugi which are wooden nails often referred to as funekugi , boat nail. To which they are still used in the construction of traditional Japanese wooden boats. They were used in all sectors of furniture and cabinet construction in Japan. Getting increasingly harder to find. They are accompanied by a pilot bit with the same taper as the wooden nail. These are a more modern invention, historically Japanese craftsman used the thin branches from a shrub I now fail to remember the name of. But would use them the same way excepting the hole would be piloted with a gimlet.

applied with a little hide glue, maybe a little less next time......

Then cut flush with a saw and smoothed with a handplane and a wisk of (doh) sandpaper.

The little door prior to glue up.

And final assembly prior to the finish.

Below the tansu sits in the shop door way soaking up some rays. The brown coat is kakishibu mixed with two secret ingredients called bengara and susu.

Kakishibu was used "back in the day" as a base coat under fukiurushi. It's a fermented persimmon juice. Not the persimmon that your used to seeing at the grocery but the astringent (shibu) persimmon (called kaki in Japan). It's a wonder juice. Cures heart disease, wards off bugs, water proofs, used as a disinfectant it is claimed to be able to kill all known virus including polio in less than 10 seconds, supposedly faster than any chemical disinfectant. I really have no proof just an interesting news blurb on Japanese tv.

But just to elaborate a little further , kakishibu is used on sill beams and ground contact posts on homes to water proof and deter wood boring beetles. Used extensively as a near annual coat on many exposed wooden components on traditional Japanese houses. Engawa floor boards, fences, gate doors, etc.... Often mixed with the above mentioned secret ingredients.

The pectin polymers create a fairly durable coating with a few or several applications that go on first like a coat of red wine but the tanins in the kakishibu will turn the color darker to a ruddish brown pretty quick in the sun. Usually thru one afternoon. There are modifiers you can use to change the hue from yellow to red, brown, black. I mean black as black. Fast too.

A thimble full is thought to be good for your heart. Early Japanese immigrants brought the shibukaki with them to Hawaii. It was something that many Japanese families grew in the yard and concocted back in the day because of all it's varied uses. And really no harder to make than fruit wine. It was also used to water proof paper umbrellas. Locally prior to monofilament fish net, Japanese fisher men would soak their linen nets in the kakishibu to make them last longer in the salt water. It's a common colorant for textiles and you'll find shirts, jeans, shoes on-line dyed with kakishibu.

But for me, it browns the mango nicely and used as a grain filler mixed with tonoko ( stone dust) or kikuso (wood dust) the pectin polymers harden and lock the fillers in the pours of the wood, coloring all at the same time. Water soluble and won't kill you or the environment. Only draw back is that it's ridiculously expensive in the USA.

tops of the two completed sections below

Some pics of the hardware in process.....

Below is the lock plate marked out from a stencil and some of the plate cut away with a cold chisel.

Then filed to the line.....

Hinges in process

Side handles

example of how sheet steel reacts to being cut with a chisel.

here's a pic of my gas forge. nice little portable unit. In the chamber is a block of 4140 steel that became my nail heading block and a tire iron I straightened out and forged a four sided taper to make the square hole in the heading block.

I hope Dave J is reading , don't I have some questions for you LOL

Above is my nail forge with two irons in the fire. Perfect size for small nails made from 1/8" round stock.

I heard 200 nails in a day was pretty good, I was able to do 260 one day , but Ryohei's nails are much nicer. In all I think I made around 700 to pick out the best 500 then another 35 or so were more small "rose head" nails I used for drawer handle bumpers.

All the edges are hand filed to a neat bevel and a irisumi corner.

535 holes were drilled for the 535 small nails.

The three way corners need to be cut out and bent very precisely to achieve 6 - 90 degree corners.

I do not like the look of clean ,flat, shiny, sheet steel parts. The process of cutting out the parts with a chisel leads you to having to correct the inevitable distortions in the part from the displacement of the steel around the cut line created by the bevel of the chisel as it sheers the steel. The process of working the parts,cold and hot ,will give them a mostly forged look but just to give it a little more vintage feel I threw them in the pacific ocean for a couple days.

Mostly to cure them of any plain, shiny areas that remained.

Then a quick acid bath to remove the surface rust followed by a bath in a base solution to neutralize the acid leaving behind the rust textured surface.

Here they are after the blackening with used oil from an excavator. Sorry not pics of that process. I know I burned less oil than the average 18 wheeler does in a single day, but I bet the EPA would not approve. Lastly they get a good coat of bee's wax melted into the surface and buffed off.

Many thanks for checking it all out. The Tansu is currently available for sale, contact with message or email if you would like to own it. I do have intention to enter it in a up coming wood show so I may not be able to offer it "artist direct" after January 13 2018. Most tansu sell during the first couple weeks of the show. There is however a similar but different stacking chest 60% complete that I've been working on the side. Many irons in the fire but will have it together sometime late spring early summer ,sooner if someone would like to put a finger on it. It also will have a full hardware suite. Mango with Australian Black Butte burl drawers .

Did I forget to say there was 535 hand forged nails......lol.

Happy New Year!

mahalo nui loa

MatsuKaze Woodworking

uniquely hand crafted

simple devices for inspired living